Accessories can be provided based on customer requirements.

All of En’Urga’s products are custom-made. Please provide details in the Contact Form for any modifications of performance specifications, or any change in the physical configuration of the desired instrument. A description of your application is helpful.

The mechanical patternator collects the fluid from the spay into specified bins placed either radially or angularly. These bins form a monolithic structure. The liquid is collected at the bottom the bin using tubes. The liquid collected is then automatically measured (either gravimetrically or volumetrically) to provide the distribution of the fluid into these different bins.

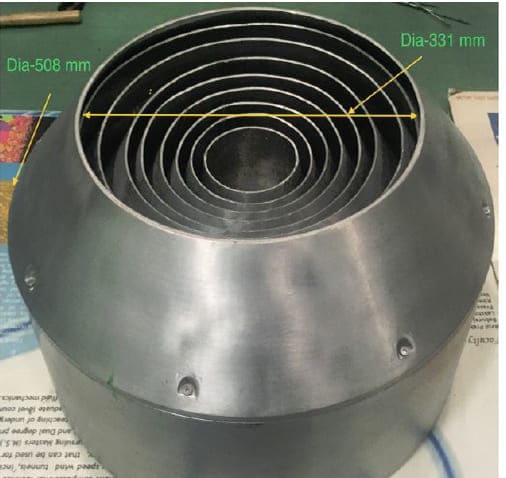

There are two types of patternators. Radial and Mechanical The radial patternator consists of eight divisions, which are concentric to each other, and bottom of each surface is designed in such a way that the fuel is directed into the hole in each division to measure the volume of the fuel as a function of the radius. This provides the radial pattern factor.

The sector patternator has eight sectors that are equally divided to form pie shaped bins. The fuel is collected into these pies and measured to provide an estimate of sector pattern factors.

The mechanical patternator is designed for thirteen inch of spray collection chamber. The top portion of each walls of the sectors are knife edge to avoid the flashback and bottom of each sectors have individual drain hole to measure the volume of the fuel.

Research and development and quality control of

All of En’Urga’s products are customizable for the customer. If a modification of the performance specifications or a change in the physical configuration of an instrument is desired please provide detail below in the information reuest form. A description of your application would also be helpful.